I-Surface Mount Technology (SMT) ihamba phambili ekuhlanganiseni izinto zesimanje ze-elekthronikhi. Ikhono lokubeka izingxenye ngokushesha nangokunembile kumabhodi esekethe libalulekile embonini yanamuhla yezinto zikagesi ezisheshayo. Enhliziyweni yalobu buchwepheshe kunezingxenye ezihlukahlukene, ngayinye isebenzela injongo yayo eyingqayizivele. Ake singene ngezigaba nasezindimeni zalezi zici ezibalulekile.

1. Ukunyakaza Nokunemba: Ukuqinisekisa Ukunemba Kuzo Zonke Izinyathelo Zendlela

Injini yomshini we-SMT ihlinzeka ngomshini wokushayela odingekayo ukuze unyakaze kahle. Noma ngabe ukuma ngokushesha kwekhanda lokubeka noma ukuslayida okushelelayo kweziphakeli, injini iqinisekisa isivinini nokunemba ekuvumelaniseni.

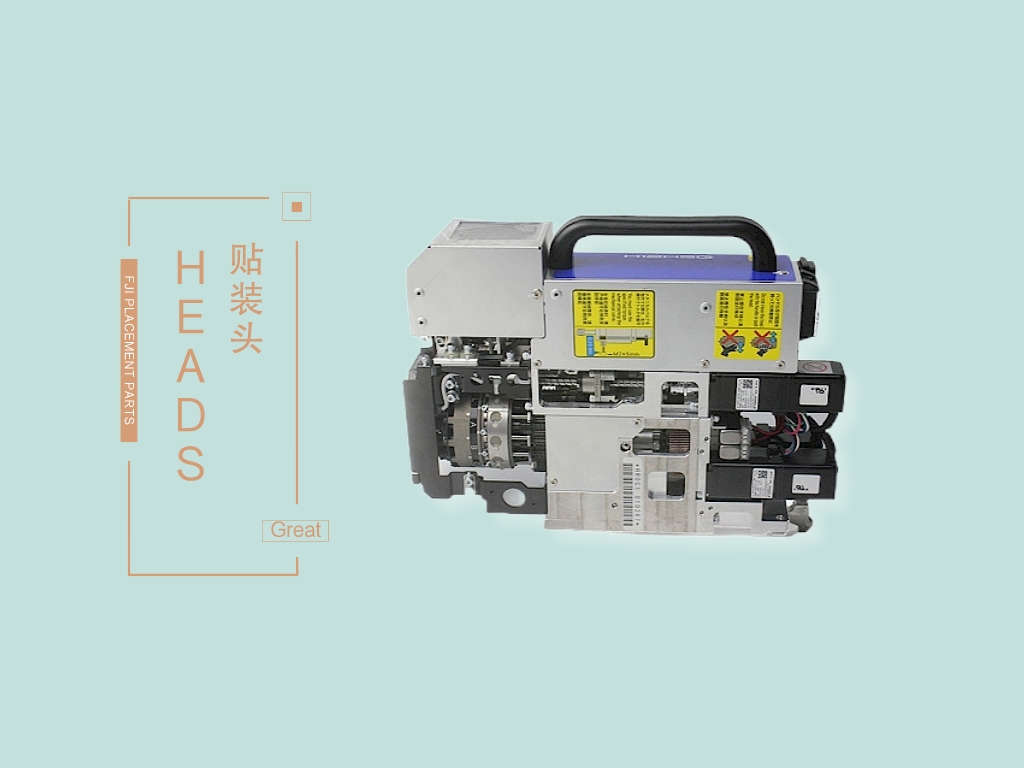

Le ngxenye inesibopho sokucosha izingxenye ze-elekthronikhi futhi ibekwe ngokunembile ku-PCB. Idinga ukunemba, futhi ukusebenza kwayo okushelelayo kubaluleke kakhulu ekuhlanganiseni okungenasici.

Le divayisi ihumusha ukunyakaza okuzungezayo kuya kumnyakazo womugqa onokungqubuzana okuncane, okuvumela ukulawula okunembayo nokunyakaza, ikakhulukazi emisebenzini yokubeka.

Njengoba nje ibhande lishayela i-pulley, ibhande le-SMT libalulekile ekugcineni ukuvumelanisa kwezingxenye ezihlukahlukene ezihambayo, ukuqinisekisa ukuhamba komsebenzi okushelelayo.

2. Ukuphathwa Kwengxenye: Ukuletha Ukungaguquguquki kanye Nempumelelo

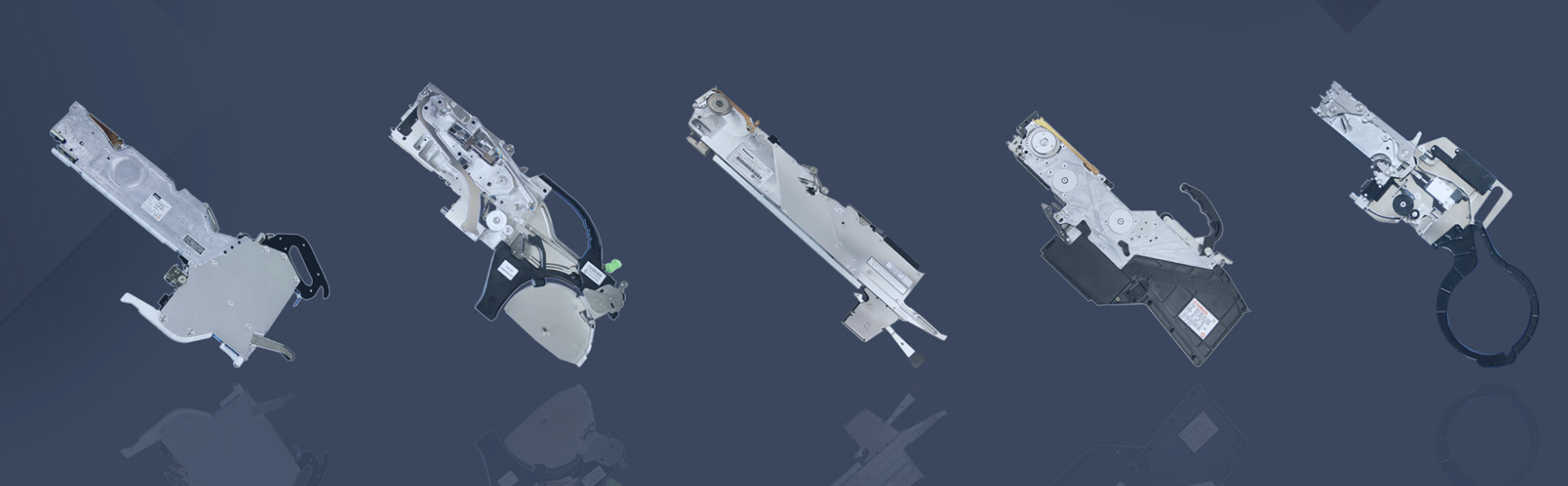

Isiphakeli se-SMT sidlala indima ebalulekile ngokuqinisekisa ukuthi izingxenye zinikezwa ngokuqhubekayo enhlokweni yokubeka. Kufana nebhande lokuthutha lomhlaba we-SMT, liletha ingxenye ngayinye ngesikhathi nje sokubekwa.

3. Ukuxhumana kanye Nomyalo: Izingqwele Zezokuxhumana

Esebenza njengomhumushi, umshayeli we-servo uqinisekisa ukuxhumana okungenamthungo phakathi kwesoftware nezingxenye zomshini, ukuhumusha imiyalo ibe yizenzo.

Isikhungo sokusebenza kwezinzwa, lawa mabhodi acubungula amasignali futhi aqondise ukusebenzisana okuvumelana kwazo zonke izingxenye zomshini.

4.Ukugcina Ubumsulwa kanye Nokugeleza Okulula: Ingqikithi Yokungabi Nasici

Ukusebenza endaweni ehlanzekile kubalulekile. Isihlungi se-SMT siqinisekisa ukuthi noma yikuphi ukungcola kuyasuswa, kuvimbele ukonakala okungaba khona futhi kuqinisekiswe ukuphila isikhathi eside kokubili komshini nomkhiqizo wokugcina.

Njengoba inomsebenzi wokulawula ukugeleza, le valve iqinisekisa ukuthi kwakhiwa i-vacuum efanele, ebalulekile ekucosheni izingxenye noma ekuqinisekiseni uphawu olungangeni moya phakathi nezinqubo ezithile.

5. Ukutholwa kanye Nempendulo: Izinzwa Zemishini Ye-SMT

Izinzwa emishinini ye-SMT zithola amapharamitha ahlukahlukene njengobukhona bengxenye, ukunemba kokuma, nokuningi. Banikeza impendulo yesikhathi sangempela, eqinisekisa ukuthi noma yikuphi okudidayo kuyatholwa futhi kusingathwa ngokushesha.

Lezi izintambo zokuphila ezithwala amasignali phakathi kwezingxenye ezahlukene zomshini. Kusukela ekunikezeni amandla amamotho kuya ekudluliseleni idatha phakathi kwamabhodi nezinzwa, izintambo zingabathwali abathule bolwazi olubalulekile.

Emhlabeni oyinkimbinkimbi wokuhlanganisa i-SMT, kusobala ukuthi yonke isiqephu, kusukela ku-Ball Screw kuya kukhamera ye-SMT, ibalulekile ekusebenzeni okuphezulu. Uma ufuna ukusebenza kahle kokukhiqiza okuphezulu, ukuqonda nokugcina lezi zingxenye kubalulekile. Ngaso sonke isikhathi beka phambili ikhwalithi, ikakhulukazi lapho uthola izingxenye, ukuze uqinisekise ukuthi umshini wakho we-SMT usebenza ngokusemandleni awo.

www.rhsmt.com

info@rhsmt.com

Isikhathi sokuthumela: Oct-27-2023