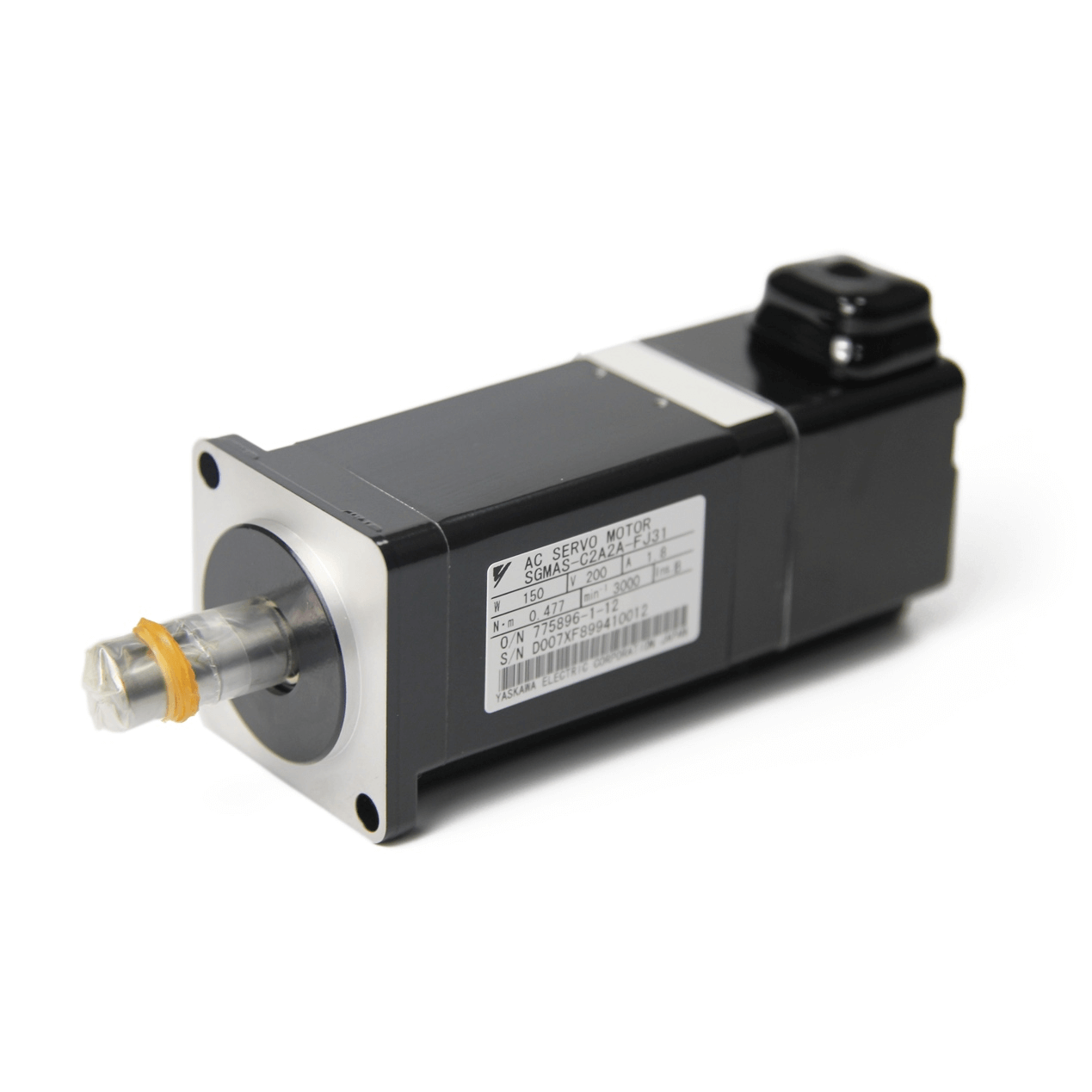

Umfanekiso 1: I-Servo motor iyingxenye eyinhloko yesistimu ye-servo.

Ngokuthuthukiswa kolwazi, ukuxhumana kanye nobuchwepheshe obuzenzakalelayo, izinhlobonhlobo zamadivayisi okulawula okuzenzakalelayo asetshenziselwe ukukhiqizwa kwezimboni kanye nempilo yansuku zonke yezwe lanamuhla. Njengenye yemishini ejwayelekile yokulawula okuzenzakalelayo, isistimu ye-servo, eyakhiwe yi-servo motor kanye ne-servo drive isetshenziswe kabanzi ekuphileni kwethu kwansuku zonke.

Ngendatshana yethu lapha, ungathola ukuqonda okujulile lapho i-servo motor ne-servo drive ingasetshenziswa khona.

1. Iyini iServo System?

I-Servo system, iwuhlelo lokulawula impendulo olusetshenziselwa ukulandela ngokunembile noma ukukhiqiza kabusha inqubo.

Njengenye yezingxenye ezibalulekile zesistimu ye-servo kanye nengxenye yokwenziwa kwayo, i-servo motor ishintsha indawo yento, umumo, isimo kanye nobunye ubuningi obulawulwayo obulandela okokufaka (noma inani elinikeziwe).

Umsebenzi wayo ukukhulisa, ukuguqula nokulawula amandla ngokuvumelana nezidingo zomyalo wokulawula, ukuze i-torque ephumayo, isivinini kanye nokulawula isikhundla sedivayisi yokushayela kuguquguquke kakhulu futhi kube lula.

2. Izingxenye Zohlelo Lwe-Servo

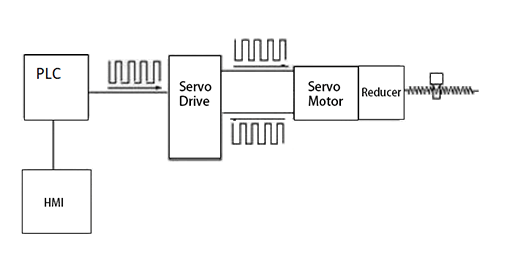

Uhlelo ikakhulukazi lwakhiwe HMI touch screen, PLC, servo drive, unomphela uzibuthe synchronous servo motor. I-servo motor iyindlela yokuphatha yokunyakaza. Isebenza ngokuma, isivinini kanye nokulawula kwamanje, ukuze ihlangabezane nezidingo zokusebenza komsebenzisi.

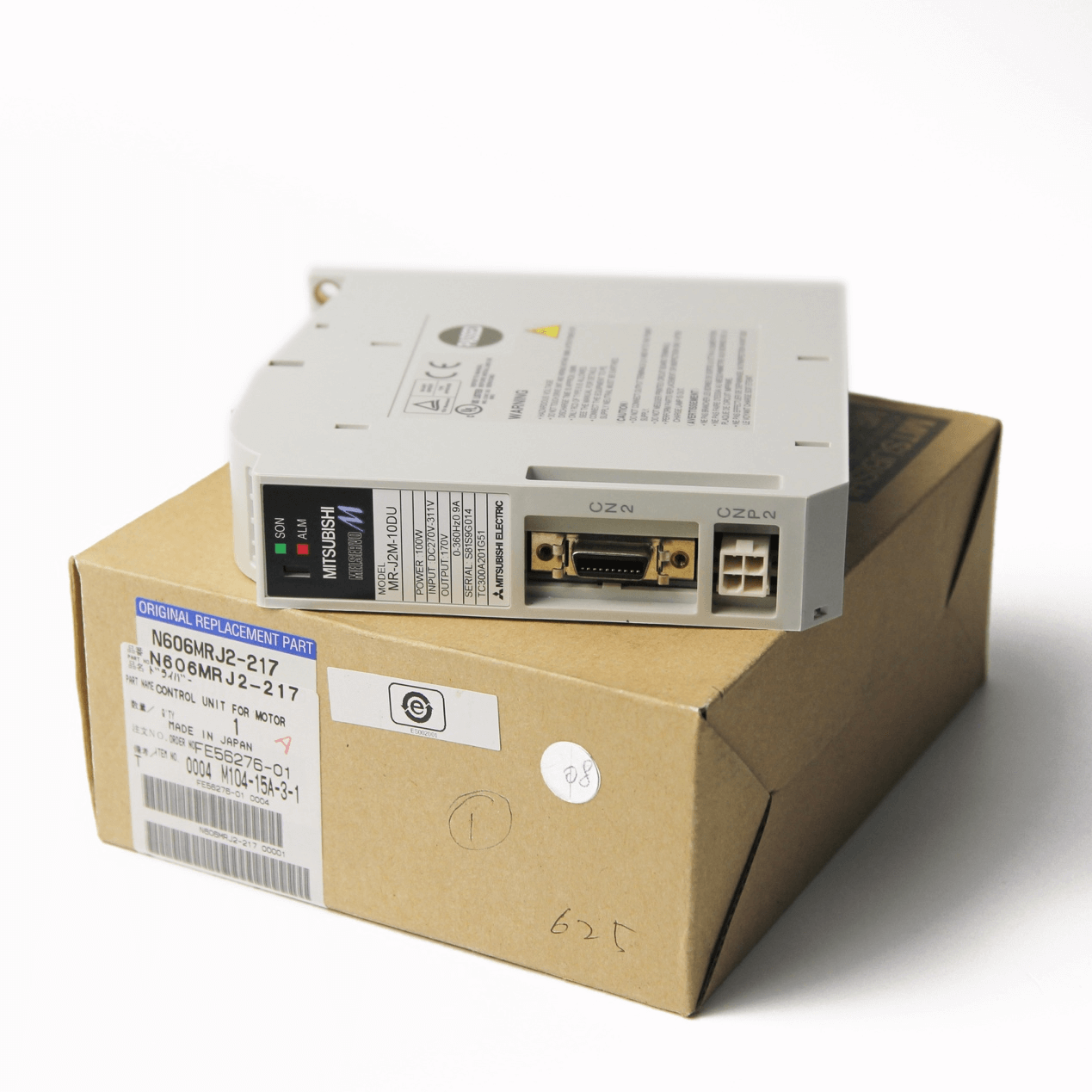

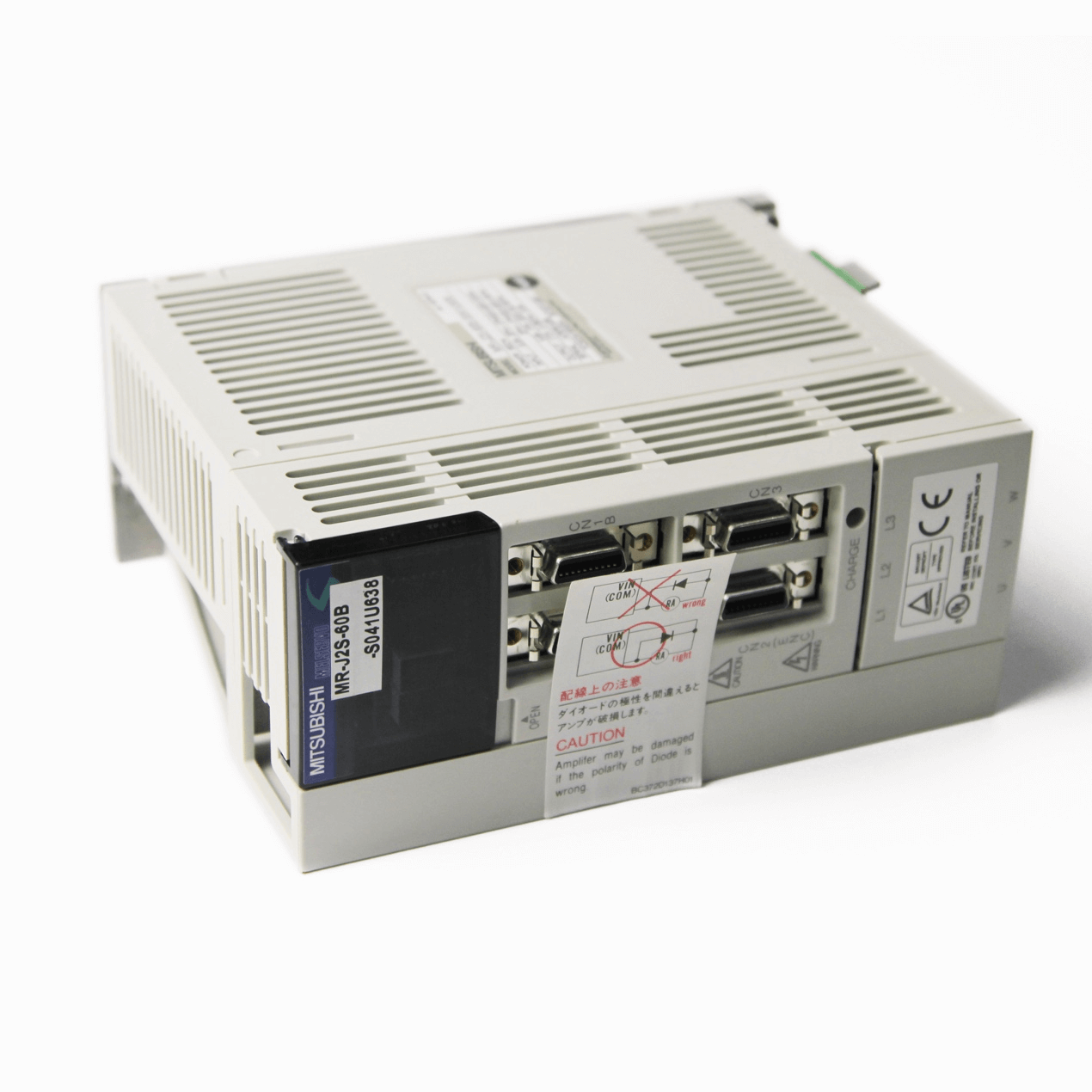

Umfanekiso 2:Uhlelo lwe-Servo lwakhiwa i-PLC, idrayivu, i-motor, i-reducer kanye ne-interface.

3. Izici, Ukusetshenziswa kanye Nezinhlobo Zesistimu Ye-Servo

3.1 IZICI ZOHLELO LWE-SERVO

Idinga idivayisi yokuthola enembile ukuze ibhale isivinini esivaliwe kanye neluphu yendawo.

Impendulo Ehlukahlukene kanye Nezimiso Zokuqhathanisa

Kunezinhlobonhlobo zezimiso nezindlela zokuqhathanisa impendulo. Ngokwezimiso ezihlukene zedivayisi yokuthola ukuze kuzuzwe impendulo yolwazi nezindlela ezihlukene zokuqhathanisa impendulo, kukhona ukuqhathanisa ukushaya kwenhliziyo, ukuqhathanisa kwesigaba kanye nokuqhathaniswa kwe-amplitude ekusetshenzisweni okuvamile.

Ukusebenza okuphezulu kwe-Servo Motor

Kumathuluzi omshini we-NC wokucubungula indawo esebenza kahle futhi eyinkimbinkimbi, isistimu ye-servo ngokuvamile izoba senqubweni yokuqala nokubhuleka njalo. Ngakho-ke isilinganiso se-torque ye-motor kuya kumzuzu we-inertia siyadingeka ukuthi sibe sikhulu ngokwanele ukukhiqiza i-acceleration enkulu noma i-torque yokubhuleka. Futhi futhi i-servo motor iyadingeka ukuthi ibe ne-torque enkulu eyanele ngesivinini esiphansi nokusebenza okushelelayo, ukuze kuncishiswe isixhumanisi esimaphakathi ekuxhumekeni nengxenye enyakazayo yemishini.

Uhlelo Lokulawula Olwenziwa Kahle Olunesivinini Esihlukahlukene

Uhlelo olunohlu olubanzi lokulawula isivinini, okuyisistimu ye-speed servo. Kusukela esakhiweni sokulawula sesistimu, isistimu yokuvala iluphu evaliwe yamathuluzi omshini we-CNC ingabonwa njengesistimu yokulawula okuzenzakalelayo evaliwe kabili enokulungiswa kwendawo kuluphu yangaphandle nokulungiswa kwesivinini kuluphu yangaphakathi.

Inqubo yangempela yokusebenza yangaphakathi iwukuguqula okokufaka kwesikhundla kube isignali yesivinini ehambisanayo, bese isiginali izoshayela i-servo motor ukuze ibone ukususwa kwangempela. Ukunyakaza okuyinhloko kwamathuluzi omshini we-CNC kudinga ukusebenza kokulawula isivinini esikhulu, ngakho-ke isistimu ye-servo iyadingeka ukuthi ibe uhlelo lokulawula olwenziwa kahle olunobubanzi bejubane elibanzi.

3.2 UKUSETSHENZISWA KOHLELO LWE-SERVO

Lawula umthwalo wamandla aphezulu ngesignali yemiyalo yamandla aphansi.

Ilawulwa yi-shaft yokufaka ukuze kuzuzwe ukudluliswa kokuvumelanisa okukude.

Yenza okuphumayo kokushintshwa komshini ulandelele ngokunembile isignali kagesi, njengokurekhoda nethuluzi elibonisayo, njll.

3.3 IZINHLOBO EZEHLUKILE ZOHLELO LWE-SERVO

| Okujwayelekile | Izinhlobo |

| Isici sezingxenye | *Isistimu ye-servo kagesi |

| * Uhlelo lwe-Hydraulic servo | |

| * Isistimu ye-servo kagesi-hydraulic | |

| *Isistimu ye-servo kagesi-kagesi | |

| Izinto ezibonakalayo zokukhishwa kwesistimu | * Isivinini noma ukusheshisa uhlelo lwe-servo |

| * Isikhundla se-servo system | |

| Izici zomsebenzi wesignali | * Uhlelo lwe-analog servo |

| * Isistimu ye-servo yedijithali | |

| Izici zesakhiwo | * Uhlelo olulodwa lwe-loop servo |

| * Vula uhlelo lwe-loop servo | |

| * Isistimu ye-loop servo evaliwe | |

| Izingxenye zeDrayivu | * Isistimu ye-Stepper servo |

| * I-Direct current motor (DC motor) uhlelo lwe-servo | |

| * Alternating current motor (AC motor) servo system |

Ithebula 1:Izinhlobo ezahlukene ze-servo motor.

4. Izimboni Ezisebenzisa iServo System

Inkambu yokucubungula i-laser

Amarobhothi

I-CNC lathe field

Imishini ye-Office automation yokukhiqiza isekethe enkulu ehlanganisiwe

I-radar nezinye izinkambu zobuchwepheshe obuphezulu

5. Amathrendi Esikhathi esizayo wohlelo lokusebenza lwe-Servo System

Isistimu yokulawula okuzenzakalelayo ayithuthuki nje ngokushesha ngombono, kodwa futhi ishintsha ngokushesha kumadivayisi ayo okusebenza. Njalo eminyakeni emi-3 ukuya kwemi-5, kuba nemikhiqizo emisha emakethe.

Isici semoto yendabuko ye-AC servo ithambile futhi ukuphuma kwayo akulona inani elilodwa.

I-Stepper motor ngokuvamile iyilophu evulekile yokulawula futhi ayikwazi ukutholakala kahle. I-motor ngokwayo nayo inesifunda se-velocity resonance.

Uhlelo lokulawula isivinini lwe-PWM lunomsebenzi ongemuhle wokulandela indawo. Ukulawulwa kwesivinini sokuguqulwa kwemvamisa kulula kodwa ngezinye izikhathi ukunemba akwanele.

I-DC motor servo system, nokusebenza kwayo okuhle kakhulu, isetshenziswe kabanzi ohlelweni lwe-servo yesikhundla. Kodwa ububi bayo, njengesakhiwo esiyinkimbinkimbi, ukungqubuzana okuphawulekayo endaweni efile ngesivinini esiphansi kakhulu, Futhi ibhulashi elihlehlayo lizoletha inkinga yomsindo kanye nokugcinwa.

Uzibuthe omusha unomphela we-AC servo motor ikhula ngokushesha, ikakhulukazi uma isishintshile indlela yokulawula ukusuka kumagagasi ayisikwele kuya kumagagasi e-sine. Ukusebenza kwesistimu kungcono, futhi ijubane layo libanzi, lenza kahle kakhulu ngesivinini esinensayo.

Isikhathi sokuthumela: Feb-10-2022